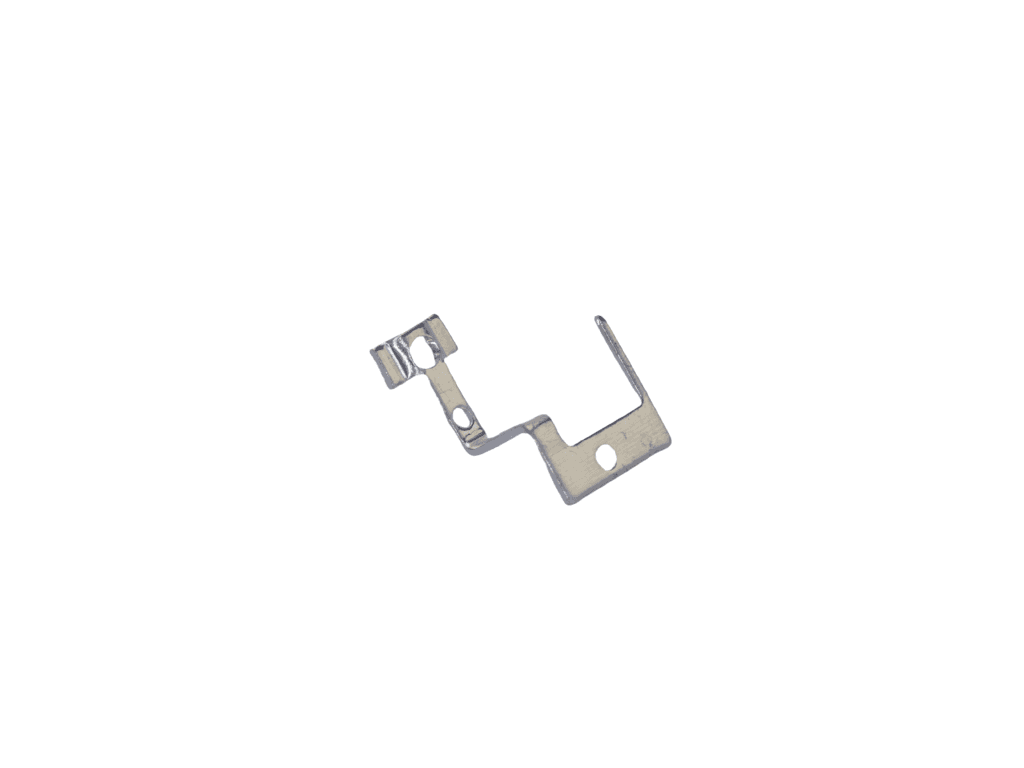

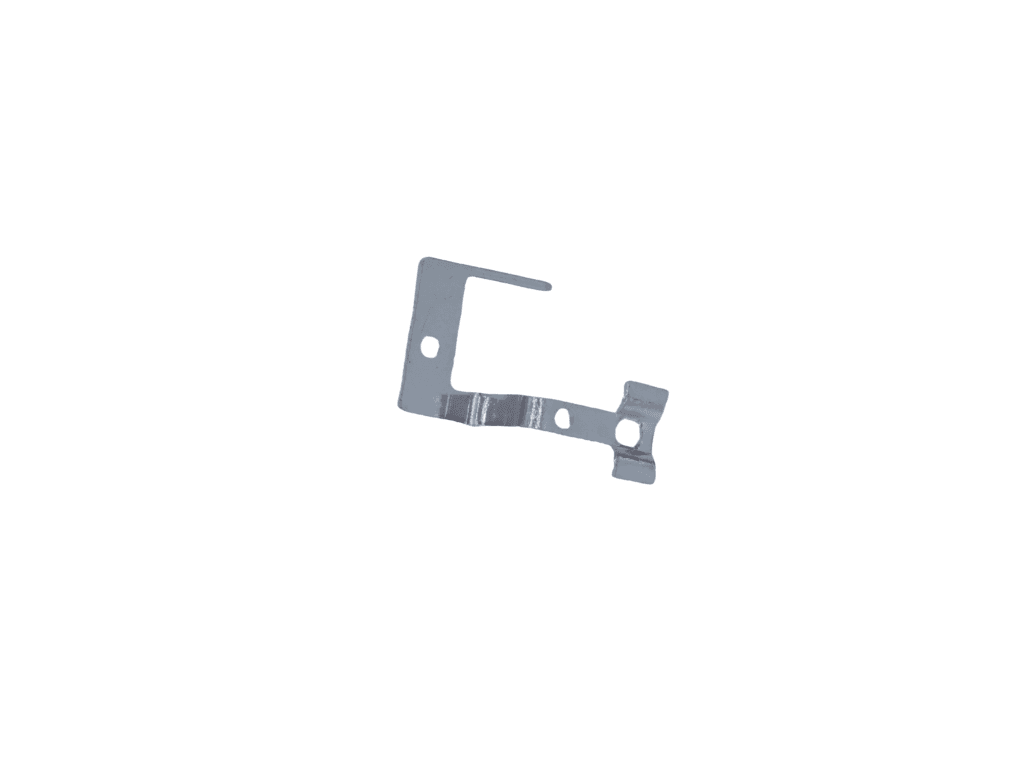

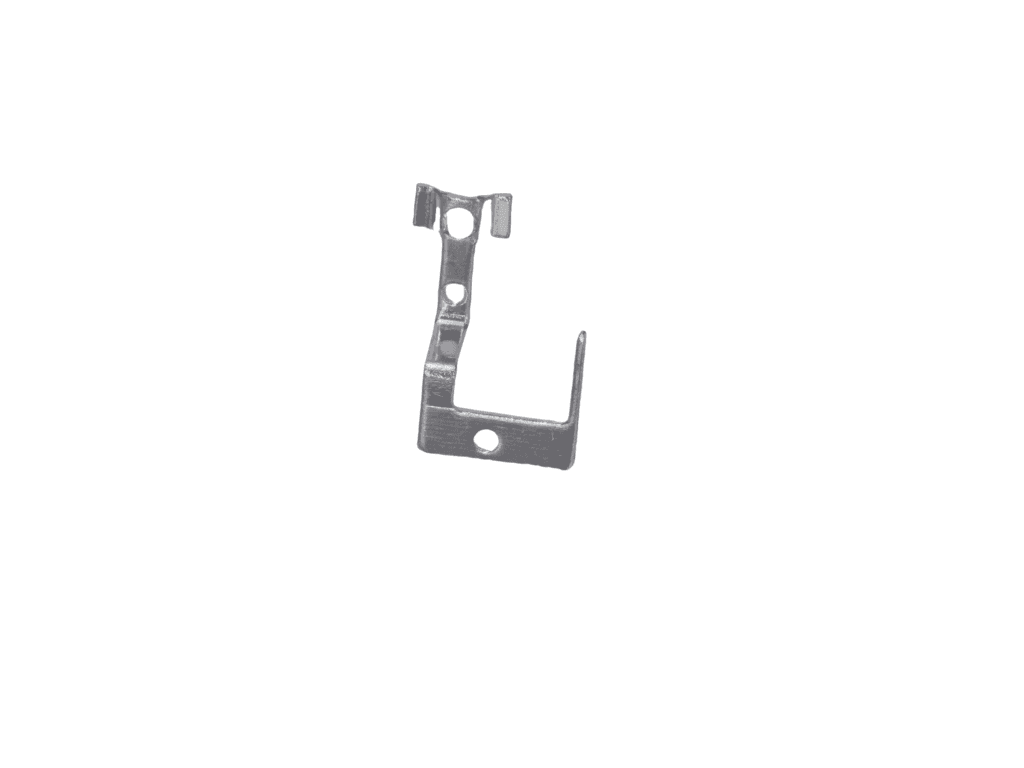

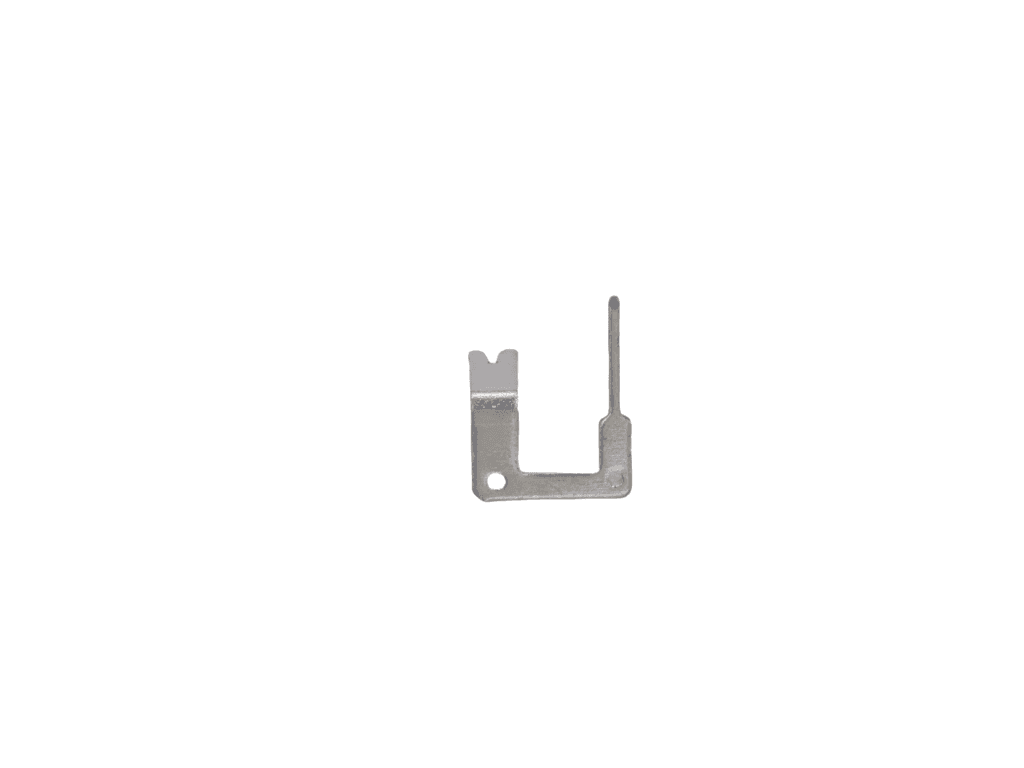

1. High-precision machining: These hardware parts use high-precision machining equipment and process technology in the manufacturing process, such as slow-feeding wire, precision high-speed punch presses, etc., to ensure that their dimensions, shape and positional accuracy to a very high standard. High-precision machining not only ensures the precise coordination between the hardware and other parts of the loudspeaker, but also improves the overall sound quality performance of the loudspeaker.

2. High-quality materials: In order to meet the high requirements of speakers for sound quality and durability, precision hardware is usually made of high-quality materials, such as high-quality phosphor bronze, brass, carbon structural steel, Stainless steel and so on. These materials have good mechanical properties, corrosion resistance and wear resistance, and can maintain stable performance under various environmental conditions.

3. Complex shape design: The precision hardware of speakers often has complex shape design, such as gear teeth, insert PIN, magnetic circuit system, etc.. These shape designs help optimize the internal structure of the speakers and enhance the sound quality and sound effects.

4. Surface treatment: In order to improve the corrosion resistance and abrasion resistance and other properties of precision hardware, it is usually necessary to carry out surface treatment, such as plating, oxidization and so on. These treatments help to improve the service life of the hardware and the overall performance of the speaker.

5. Customized production: Due to the wide range of models and specifications of speakers, precision hardware often needs to be customized according to specific needs. We carry out precise processing according to the drawings and requirements provided by customers to ensure the perfect match between hardware and speakers.

6. Strict quality control: During the manufacturing process, we strictly manage quality and process control, and strictly check each link. This includes the inspection of raw materials, the monitoring of processing, the testing of finished products, etc. to ensure the consistency and stability of the quality of precision hardware.